What is XRT Sorter?

Based on the sensor technology and X-ray transmission technology, the XRT Intelligent Mineral Ore Sorter provides a brand-new solution for mineral ores sorting to remove the waste and coal gangue. The sorting system adopts our unique AI Computer algorithm to recognizes the internal physical characteristics of the extracted materials and sorting the coal and gangue away by the high-pressure blower, based on customer's requirements.

Working Principle

The equipment uses X-ray to scan the raw ore, collects data from the detector, and distinguishes the ore and waste rock through intelligent algorithm, and blow the waste rock away with the High-pressure blowers.

HOT Sorter X-Ray

Sorting by X-Ray transmission according to atomic density with HOT Sorter X-Ray

HOT Sorter X-Ray technology enables the classification of materials based on their atomic density, allowing the smallest inclusions in the material as well as the material composition of an object to be clearly determined and used for sorting. Location of the specific material within the target object does not matter -- on the surface or enclosed in the overall material. The HOT Sorter X-Ray can be used in the mineral sector for ore concentration/enrichment and for sorting out foreign materials and in the glass recycling sector where lead glass and refractory glass ceramics are detected and discharged.

Currently, XRT sorters pass high-intensity X-rays through particles to generate greyscale images based on effective atomic density. Using algorithms based on these images, the particle sorter (“ore sorter”) processes these images and is able to identify particles from each other, then mechanically separates them using air ejection mechanisms.

The optimal particle size for sorting is a function of the ore’s mineralization, the commodity being extracted and the sensitivity of the sensor used in the sorting equipment.

Main Structure

l Feeding system:The belt conveyor is used to make the ore stably enter the scanning area to ensure the accuracy of detection and separation.

l Detecting system:An X-ray source is installed on the top of the system and, after the ray irradiates the ore, the detector receives the X-ray signal and converts & collects it. Then uploads it to the data processing system.

l Data Processing system:Using the AI algorithm to analyze the ore image and data, achieving the recognition of the ore and waste. At the same time, it is decided whether the target ore (waste) needs to be removed by blowing.

l Executing system:The target ore is ejected away from the original route by the power of the high-pressure pneumatic blowers to achieve the purpose of separation.

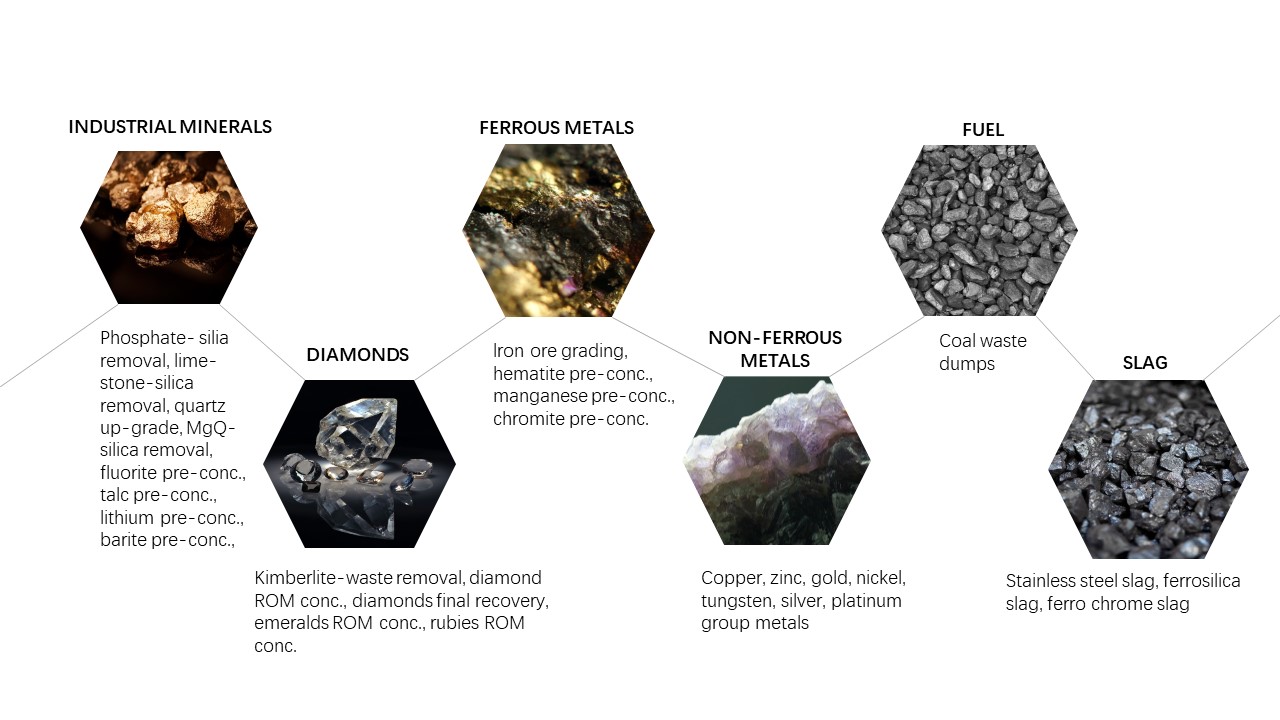

Does It's Used in Coal Only? -NO

The sorting machine has been successfully used in tungsten, tin, antimony, lead-zinc, copper, gold, silver, molybdenum and other metal mines, as well as non-metal mines such as coal, fluorite, phosphorus, Ferro sulfide, etc. Our sorting machine is currently the only X-ray intelligent sorting machine with mature application cases in non-ferrous metal ore, ferrous metal ore, non-metallic ore, coal mine and other fields.

Technical Parameters

Item | Content | Note |

Raw Materials | It’s suitable for the ore of tungsten, tin, antimony, lead-zinc, copper, gold, silver, molybdenum and other metal mines, as well as non-metal mines such as coal, fluorite, phosphorus, Ferro sulfide, etc. | |

Sorting Technical Principle |

XRT | X-ray transmission technology |

Equipment Structure | Feeding, Detecting, Data Processing and Waste Rejecting | |

Particle Size Range | Many ranges can be selected for different requirements. Including: +8-40mm, +12-60mm, +20-100mm, +50-300mm. | |

Productivity | 40-400t/h, decide by raw materials | |

Main Equipment Size | 9*2.3*2.5 (m) | |

Wight | 10 (t) | |

Power | <10KW |

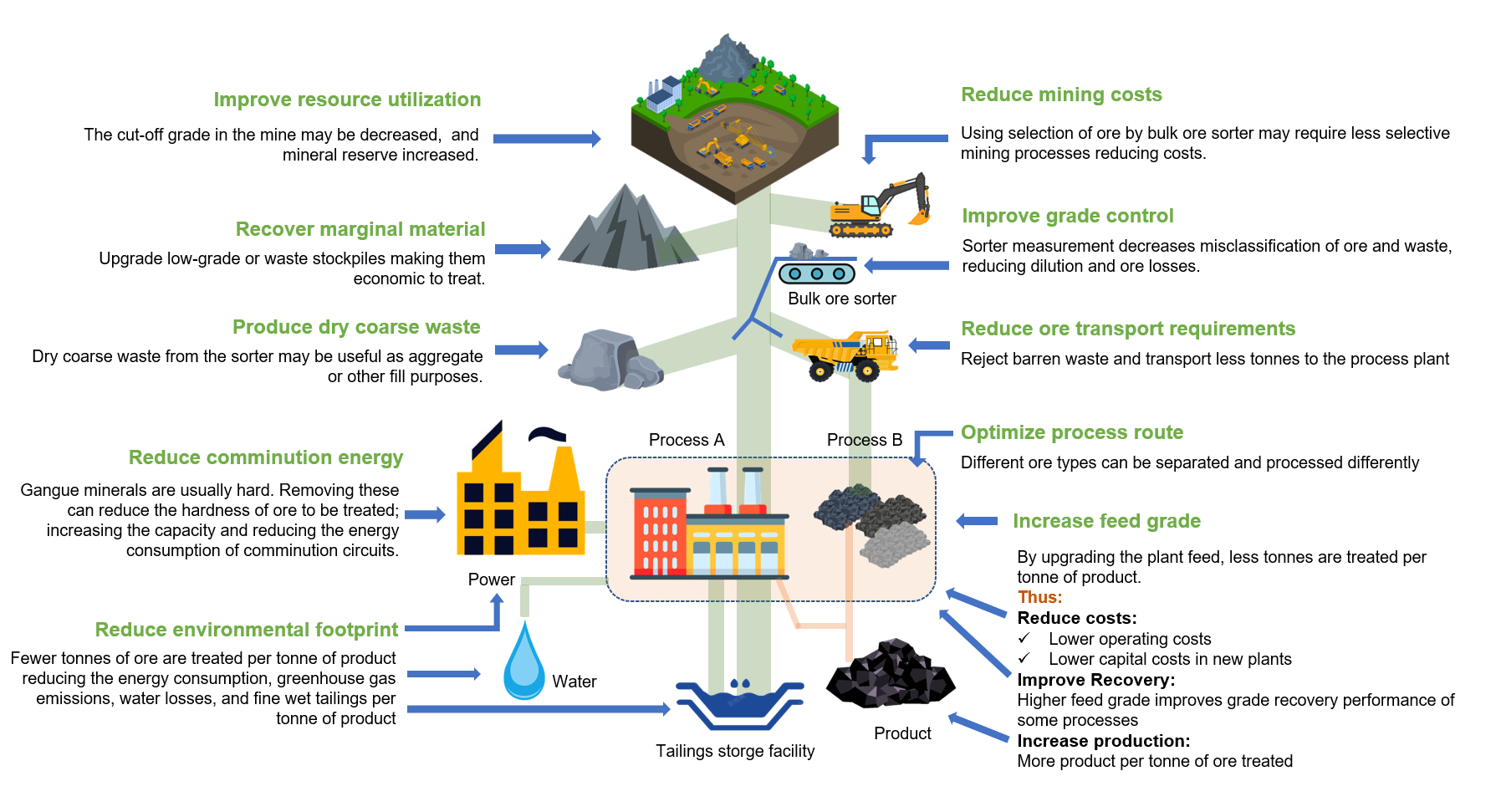

XRT Separator: Improve your Productivity

1. Wide range of particle size, including + 8-40mm, + 12-60mm, + 20-100mm, + 50-300mm.

2. The space of air blowers can be selected flexibly (7mm, 10 mm, 12.5mm) according to the requirements of ore processing capacity and the size of ore particles.

3. Among the range of + 12-60mm grain size, the average output can reach about 60-100tph; for + 20-100mm, the output is more than 120t / h. When processing large grain size coal mines, the output is as high as 400t / h.

4. The data processing system adopts high integration AI algorithm to achieve millisecond operation rate and high processing capacity of ore dressing recognition rate. Which can increase ore recognition ability and accuracy, improve ore separation accuracy and make the separator is suitable for many kinds of ores.

5. Safe operation and maintaining cost.

6. It takes replace of hand sorting in some certains with higher efficiency.

On-site Application

XRTIntelligent soter by HOT Mining Tech

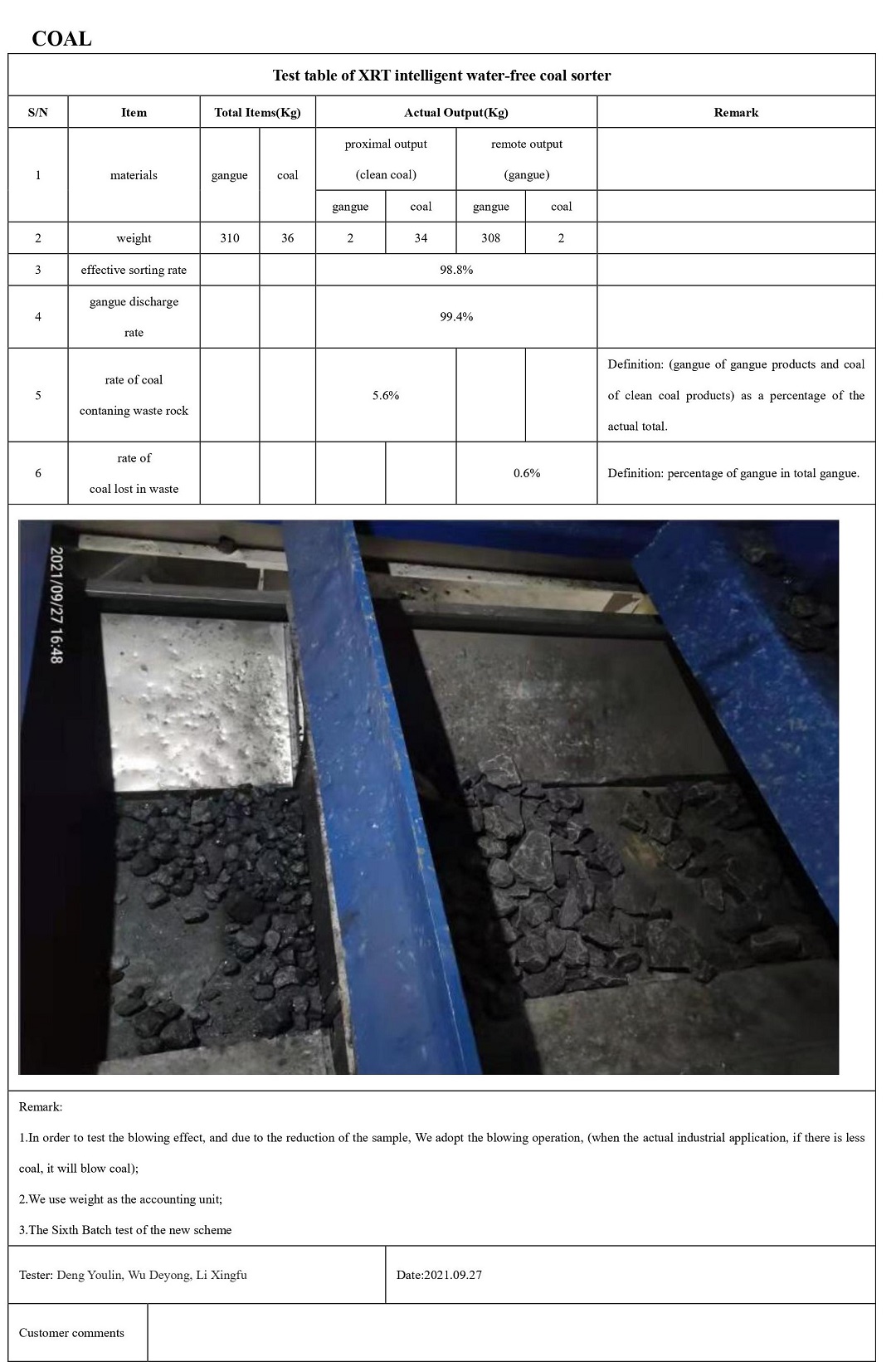

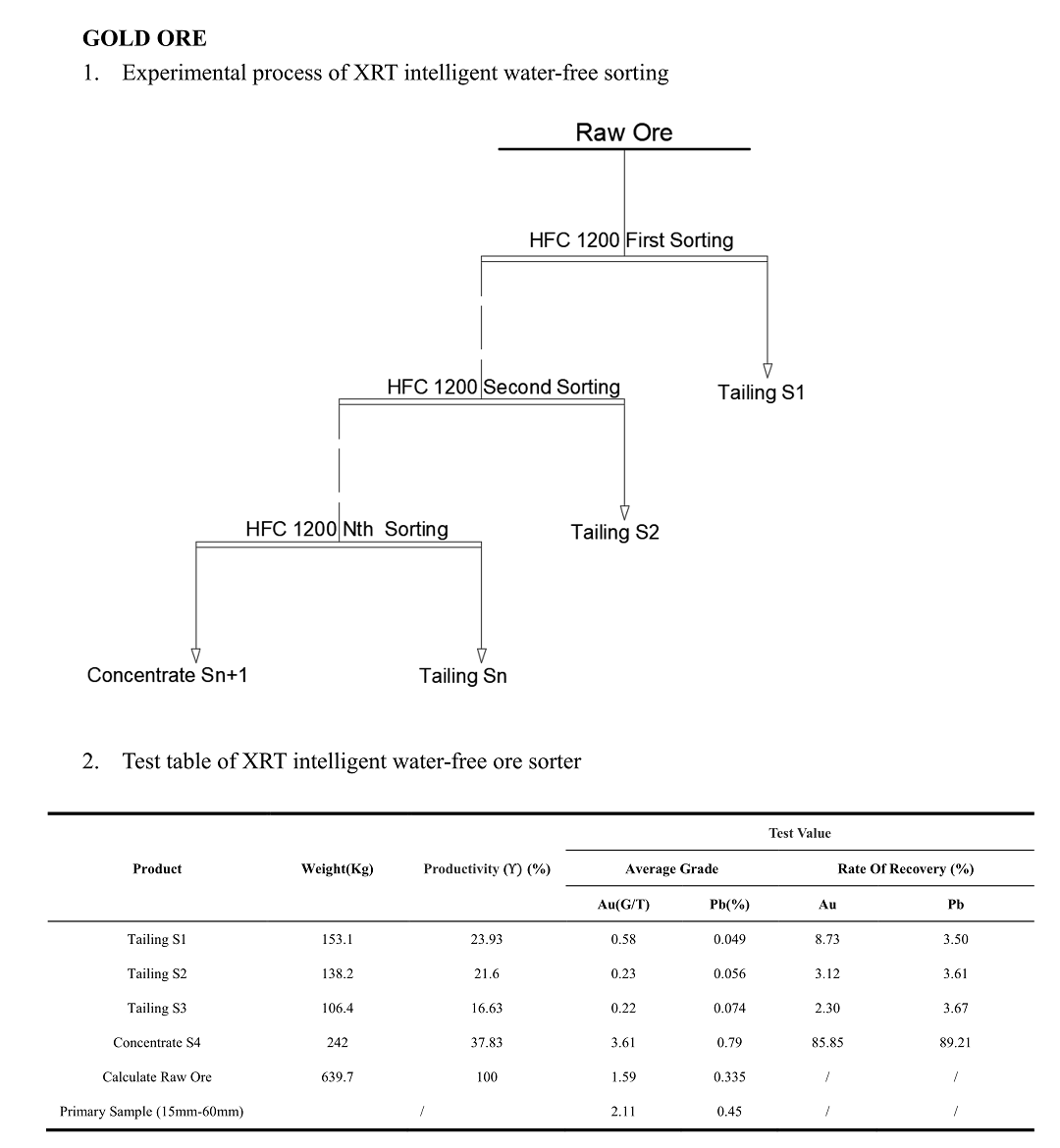

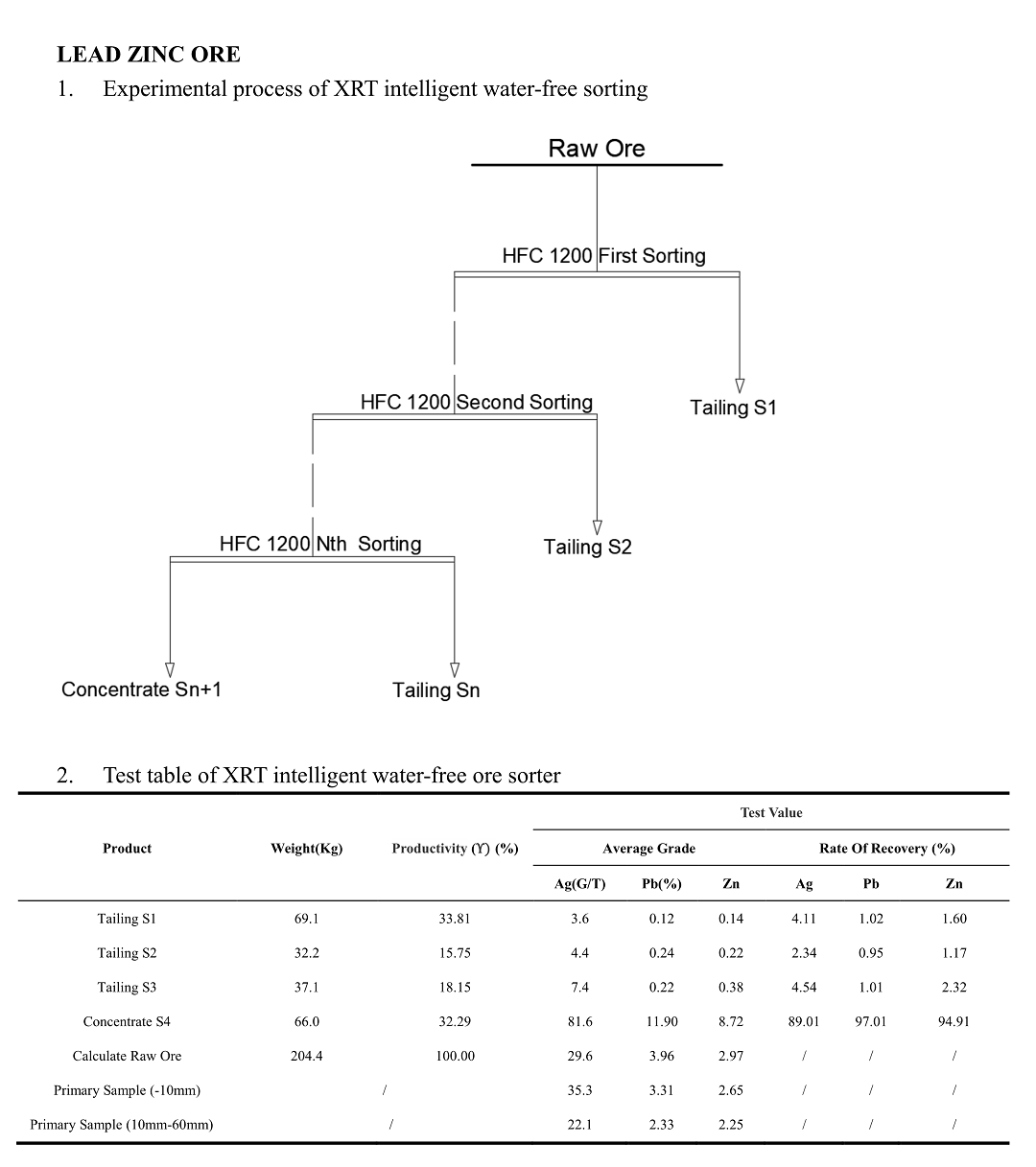

Sample tesing

Contact us

Email: sales@hot-mining.com

Tel:+86 28 8331 1885

Waste Disposal Test of XRT Intelligent Mineral Ore Sorter in a Scheelite Mineral Processing Pla

Test Analysis of Molybdenum Ore Sorting by X-ray Separator