Original by Wang Guohua from Knowledge and practice of coal preparation 2021-06-27 06:00

Translated and Re-edited by HOT (Chengdu) Industries Co Ltd

Recently, in a talk with a customer about the dense media consumption of Non-desliming and Gravity Feeding Three-Products Cyclone complete washing, I mentioned that our assessment standard was 0.45kg/t, which the customer could not believe.

That makes sense. Think about it if you have gradually accepted that your factory management can only control it at 1.5kg/t by all means and tell you that this is the national standard. Then it is unbelievable that now suddenly there is less than three times the loss.

How can we reduce the dense media consumption to 0.45kg/t? The limited condition here is the technology of Non-desliming and Gravity Feeding Three-Products Cyclone complete washing. If the condition is desliming or two products cyclone, the dense media consumption could be lower. 0.45kg/t is only an order of magnitude of the relative standard rather than the precise absolute standard. For the assessment standard, “take it up, get it in, take it in, get it down,” there is no need to obsess about the accuracy of 0.45.

Gravity Feeding Three-Products Cyclone complete washing

1. Setting Goals

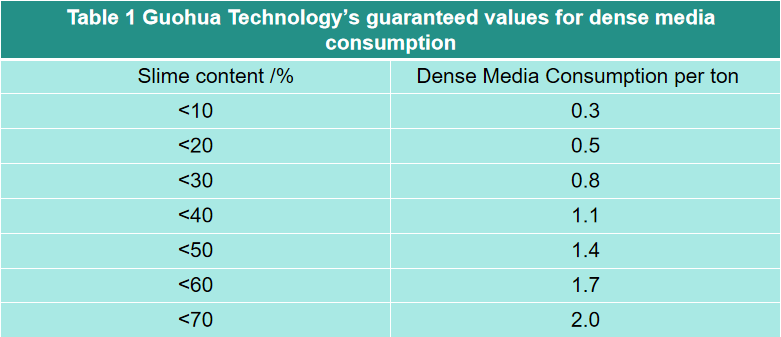

First, let's look at the feasibility of reducing the dense media consumption to 0.45kg/t. Here we find two bases: First, the article “The practice of Xinyi Coal preparation plant’s ultra-low dense media consumption of 0.45kg/t”introduces that the dense media consumption of Xinyi coal preparation plant is reduced to 0.45kg/t, and its technology is precisely the non-desliming and non-pressing three-product cyclone complete washing, heavy media cyclone coal preparation technology for slime and flotation process. Second, Guohua technology on the consumption of the guaranteed value see Table 1

Table1

From the above two bases, the dense media consumption target of 0.45kg/t is feasible, and the manager of the coal preparation plant must have confidence in this target.

2. Managing Mindset

If your coal preparation plant’s current dense media consumption is 1.5-2kg/t, what strategy would you adopt to achieve a dense media consumption of 0.45? The general idea would be to add a dam-board to the media draining screen, add buffer to feed, adjust the strength and angle of the water spray, the concentration of circulating water, magnetic separation machine to deal with flopping, modify the magnetic separation machine feed buffer, replace the excellent quality of magnetite powder and so on. However, these need help to achieve the effect of triple reduction.

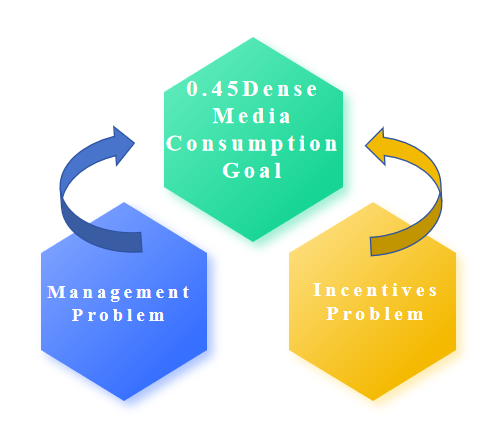

The problems needed to be tackled in order to achieve o.45 goal

Achieving the 0.45 dense media consumption target is the primary task of the coal preparation plant manager. The dense media consumption is mainly two aspects: the adhesion loss of the media draining screen and the magnetic tail loss of the magnetic separation machine. If the area of the media draining screen is more prominent and there are more magnetic separation machines, the dense media consumption will be drastically reduced. This one is simple, so it’s not a technical problem. It’s a management problem. I have always believed that “management is a trade-off.” If you want to achieve the goal of 0.45 dense media consumption and reduce operating costs, then you must be willing to invest. If the transformation site is limited, you can replace the higher price of a high-efficiency screen plate, which is a cost comparison issue.

To achieve the 0.45 dense media consumption target, followed by the incentive problem. Dense media consumption has been the topic of research papers on coal preparation plants. Online, it is easy to find a variety of practical experiences for reducing dense media consumption, but why has dense media consumption been a problem? The author believes that this is a problem in terms of incentives. The assessment of dense media consumption tends to go to two extremes:

One extreme is the strict assessment of fines; in this case, developing assessment standards is very critical. In order not to be fined in the development of standards, people will consider various objective reasons. The standard cannot be set too low; it can be completed the best. Because of this year’s completion of good, next year’s standards will be increased, not as good as just finished, so there is a 1kg/t dense media consumption standard;

The other extreme is dense media consumption as a stage of experience summary of the highlights, as a reporting material, each time will summarize some of the experience of reducing dense media consumption and get some rewards. Then the dense media consumption will be due to some reasons back to the original point, and then the next time to reduce, and then come back again, reduced n times, found that the actual dense media consumption is still so much.

3. Incentives

If the incentive problem is not solved well, the transmission cost will always be a technical problem. To get out of the evaluation cycle, the author believes that we should first clearly distinguish the goal and the task. The dense media consumption of 0.45 is the goal. If the goal is given to the grassroots, the grassroots will complete the goal as a task, but the goal will change with the degree of dense media consumption of 0.45 this year, of 0.4 next year, and finally, will end in failure.

How to translate incentives to positive performance

We should break down the goal of 0.45 into tasks, for example, into specific tasks such as how to make the magnetic separation machine not flop, how to make the screen surface of the media draining screen even, how to divert the flow of the magnetic separation machine smooth, how to make the incoming material better buffer, etc. Each task will be solved according to the employees’ experience, and the optimization of each link will be amplified through the system to form a considerable improvement.

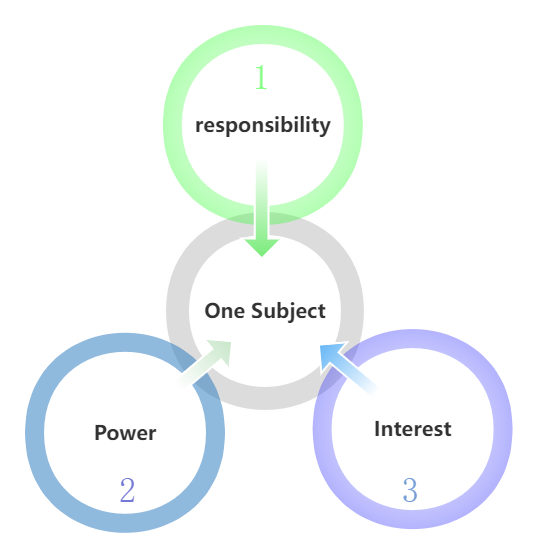

4. The Responsibility, Power and Interest Managing Mentality

To realize the 0.45 dense media loss target, there is another problem. Dense media consumption is an essential part of the cost of coal processing. For the boss, it is imperative, but for the operation of the staff, Dense media consumption is only an indicator and is an indicator to be criticized and fined, which is a responsibility and right is not equal to the problem.

The law of the responsibility, power, and interest mentality is the reciprocal relationship between responsibility, power, and interests. That is, in any management unit, responsibility, power, and interests, these three things must simultaneously and equally happen to a subject. Responsibility alone will undoubtedly give rise to passivity.

The Responsibility, Power and Interest Managing Mentality

Therefore, in the dense media consumption problem, employees should have reciprocal responsibility and rights, feel that dense media consumption caused by the increase in profit employees can also benefit themselves, so that employees will continue to improve, dense media consumption can continue to reduce.

5. Lessons Learned on Dense Media Consumption Reduction that Need Attention

There are a lot of articles and articles on the Internet. I won't go into details here, but it reminds me of two lessons that I find easy to ignore:

First, heavy media density reduction is conducive to reducing dense media consumption. This point is relatively easy to ignore because the density of rich media is based on the density of sorting decisions, often not due to dense media consumption to adjust. However, the impact of high and low density on dense media consumption is quite significant. Under this condition, the primary wash density reduction or gangue magnetic separation machine feed dilution can reduce the media loss.

Second, operating a multi-frequency shunt with a tiny amount is conducive to reducing dense media consumption. Heavy dielectric separation of the shunt on the magnetic separation machine magnetic tail loss has a significant impact. Multi-frequency, small amount of shunt operation is more conducive to reducing dense media consumption.

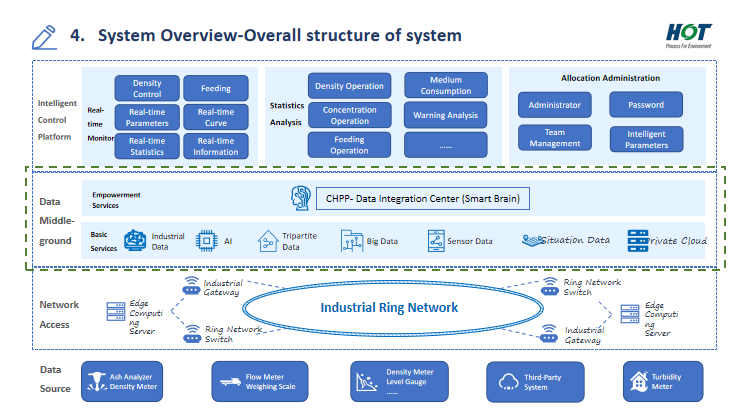

6. HOT-The AI-embedded Dense Medium Feeding Module

Dense-Medium-Feeding-Module

The AI-embedded dense medium feeding system uses key instruments like 3D level laser radar, measurement software, and an intelligent control system, along with a self-developed software platform, to optimize the additive process. It enables precise monitoring of critical data and achieves functions like 3D automatic measurement of powdered materials, automatic retrieval and measurement of powder, automated ratio control, and automatic delivery. This system fulfills the goal of dense medium feeding technology.

Dense-Medium-Feeding-Module

In Conclusion

The level of dense media consumption is not only reflected in the cost but also reflects the stability of the entire heavy media sorting system, which directly determines the quality of heavy media products. Hence, the ultra-low dense media consumption (0.45kg/t) reflects the management ability of a coal processing operation team.

To achieve ultra-low dense media consumption (0.45kg/t), it is not only necessary to find ways in technology but also to find countermeasures from the management and to achieve it through continuous optimization of the system.

Contact us:

Email: sales@hot-mining.com

WhatsApp: +86 18282103350